Over the past years, we have witnessed numerous trends and technologies disrupt the mechanical engineering sector. One of the most significant ones among them has been additive manufacturing (AM). It has not only added considerable value to the sector as a whole but has also profoundly impacted mechanical engineering courses. The usage of 3D printing technologies has enabled a lot of aspects and helped optimize a number of processes in an industrial setup. Reputed mechanical engineering colleges are constantly making efforts to stay abreast of the industry dynamics and provide students with the most updated curriculum. Inspired by the advanced technologies that have emerged in this industry, we have also seen an increase in the number of interested candidates for this subject. In this article, we will try to explore how additive manufacturing has impacted education in mechanical engineering.

Prototyping and Designing

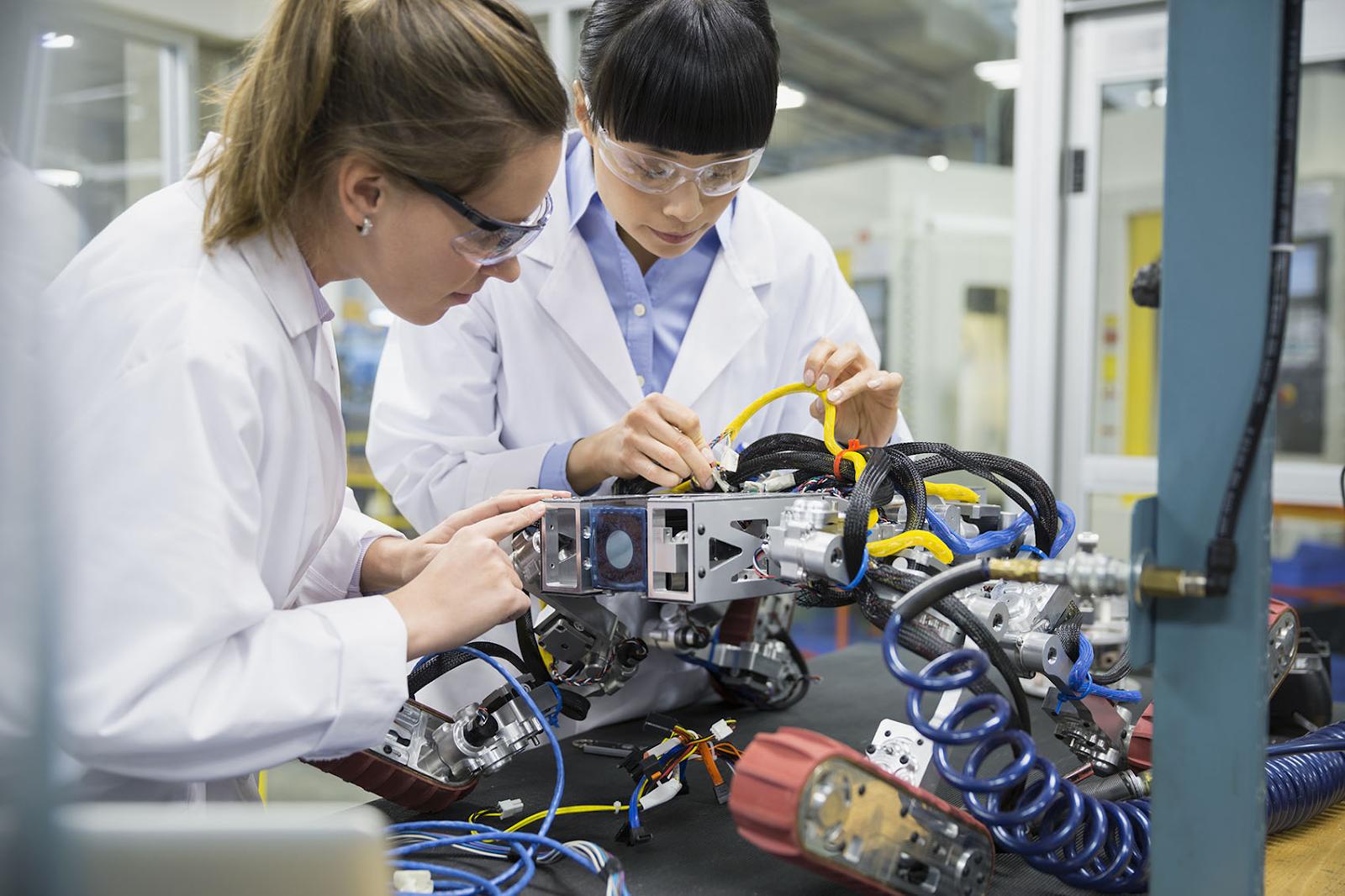

Earlier, in a manufacturing setup, there was no way to avoid the wastage of material because of sample production and approval. With the entry of additive manufacturing technologies, a permanent solution has been found for this. With the help of 3D design technologies, quick prototyping and designing have become possible. Virtual designs of products can be designed with the help of the system, and clients have the freedom to provide approval of the one that is best suited for them. Some of the most reputed B Tech mechanical engineering colleges have incorporated these systems into their campus and added the learning regarding them into their curriculum. The primary motive behind it is to provide hands-on learning to students and make them understand what is actually going on in the industry.

Industry Orientation

Today, most of the popular manufacturers of the country are shifting towards additive manufacturing and the integration of Industry 4.0 technologies into their factories. This is the reason why it has become very important for mechanical engineering colleges to include learning about the same in their curriculum. In order to have an organised approach towards this, many colleges are collaborating with engineering organisations to avail the latest industry insights. They are also organising seminars and workshops where industry veterans are being invited to share their work experiences with the students. Moreover, new technologies and processes are being incorporated into the course curriculum on the basis of the advice given to the colleges by organisations. The rise of additive manufacturing in the market has inspired many industry-academia partnerships across the country.

Developments in Material Science

One of the striking developments that the manufacturing sector has experienced because of AM is the innovation of new materials. Today, there have been many innovations in the field of material science where companies have been able to identify new kinds of raw materials that can be cost-effective and of good quality at the same time. Complete R&D setups are being established by companies that revolve around additive manufacturing technologies. This is the reason why it has also become important for B Tech mechanical engineering colleges to have a similar kind of research infrastructure on campus. For students to become trained professionals and add value to the businesses of future employers, it is important that they get trained in the same from college.

In Conclusion

Apart from the above aspects, there are many other developments that have taken place in the mechanical engineering sector because of additive manufacturing technologies. There is more sustainability in designs today, and reduced wastage has also been observed. As the industry grows and new innovations disrupt the scenario, it can be expected that additive manufacturing will bring about more changes in the mechanical engineering education in the coming days.

Write a comment ...